DEVEX Drying Technology

Vacuum and Freeze Drying

The vacuum drying technology is one of the most economical and most gentle drying methods. Due to the vacuum very low water evaporation temperatures can be reached. Aroma, product color and bulk density can specifically be influenced by the process.

Vacuum Belt Dryers are used in the Pharmaceutical Industry, Food Industry and Chemical Industry.

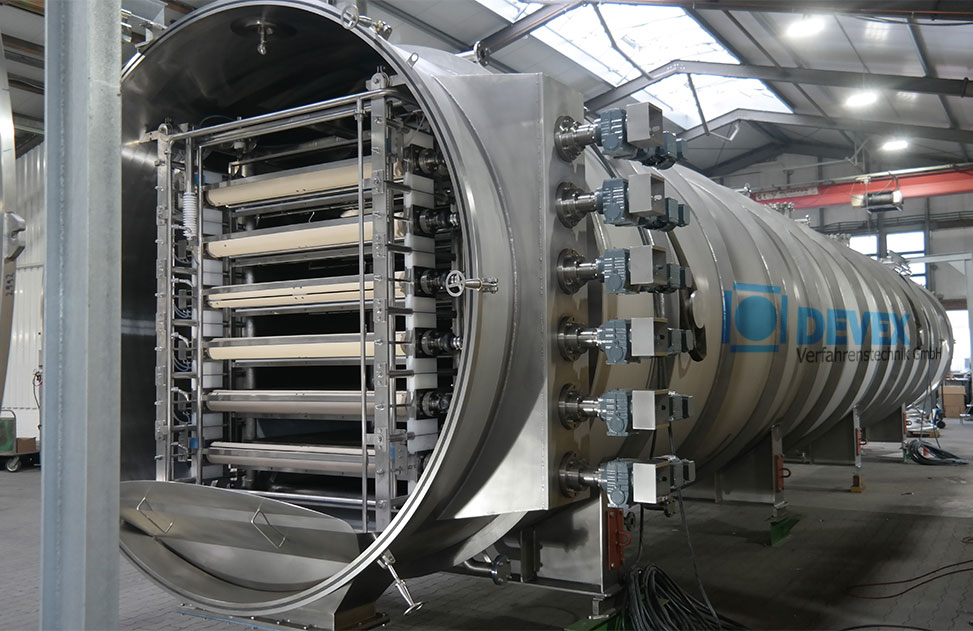

DEVEX Vacuum Belt Dryers are designed for the continuous operation with liquid or solid products. The dried granulate is also quasi-continuously discharged and can be removed under cleanroom conditions (GMP). After the drying process, the product can be ground, filled and packaged.

DEVEX Process & Product Development is pleased to assist you with the drying process and the dryer design. In our company own test center with a pilot vacuum and freeze drying plant, we are able to do product development with and for you, doing trials with your desired material and parameters, and after that scale this processes up to tailor made production equipment. Send us an inquiry to get to know more of all the opportunities.

Supply of Dryers for the Pharmaceutical Industry, Chemical Industry and Food Industry.

Dryer Types:

- Continuous Vacuum Belt Dryer

- Continuous Vacuum Freeze Belt Dryer

- Vacuum Drying Cabinets

- Pilot Vacuum Dryer

Drying Processes:

- Vacuum Drying

- Liquid Freeze Drying

- Freeze Drying of lumpy products / solids

- Native Drying without use of additives

Gentle drying of miscellaneous products:

- Plant Extracts

- Fruit Juice Concentrates

- Malt Beverages

- Pharmaceutical Products

- Hydrolyzed Vegetable Proteins (HVP)

- Instant Coffee

DEVEX Vacuum Belt Dryer for the drying of solids

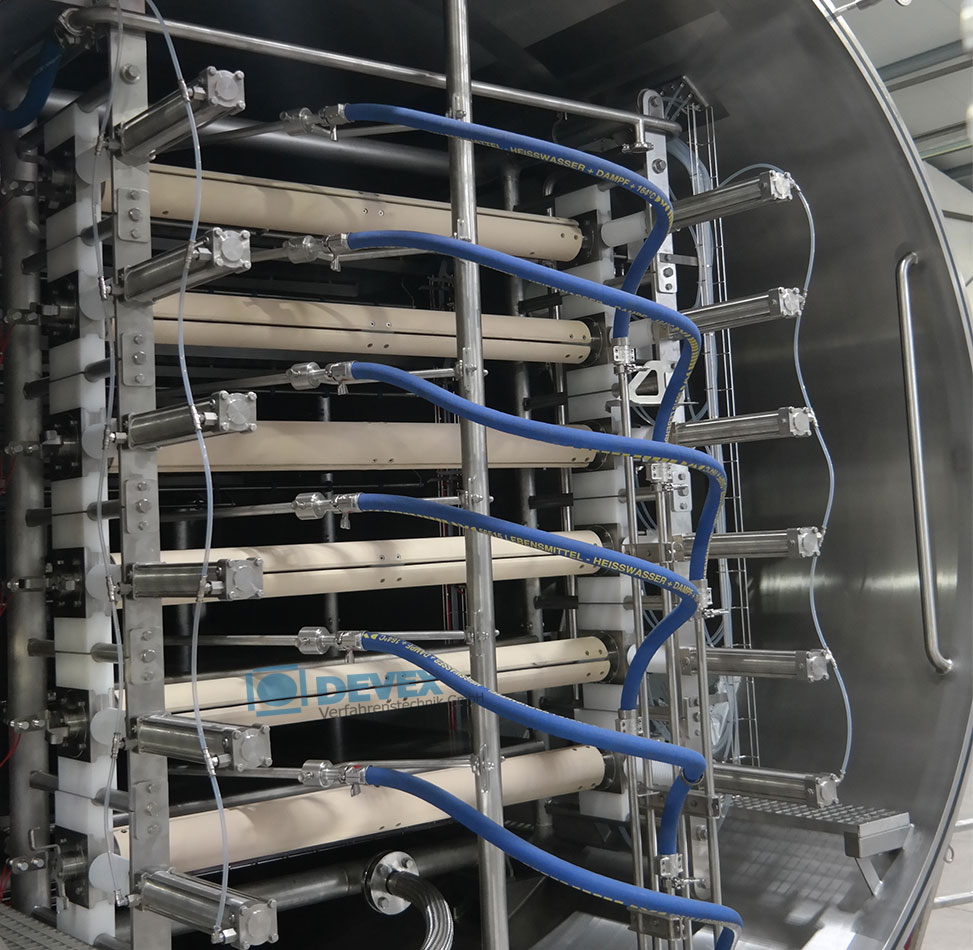

Design and customer-specific development of product feed systems, belt actuation systems, belt control systems and belts depending on customer and product requirements.

All Dryers are functionally tested before delivery:

- Vacuum test of the Dryer in operation mode

- Pressure test

- Test of the belt control system

DEVEX Freeze Drying

Freeze Dryers are commonly used in the coffee industry, but they are also used for the drying of products from the food and pharmaceutical industry.

Freeze Drying is a highly complex and technically demanding process and is one of the most gentle drying methods. Specific product characteristics, such as aroma and product color, are maintained during the drying process

DEVEX Vacuum Drying Cabinets

For laboratory and small-scale productions Vacuum Drying Cabinets are used. The size ranges between 1 – 20 m² drying surface.

Vacuum Drying Cabinets can be used for multiple applications, e.g. for the drying of extracts, powders and emulsions. Depending on the type of use, Vacuum Drying Cabinets are equipped with heating plates or heating jackets. Vacuum Drying Cabinets are operated in batch mode.

Advantages for the use of Vacuum Dryers:

- low product temperatures

- minimal loss of flavors

- very small product loss

- no product oxidation

- no mechanical stress to the product

- controllable Maillard reaction

- controllable solubility (instant characteristics) of the dried products

- possibility to recover solvents

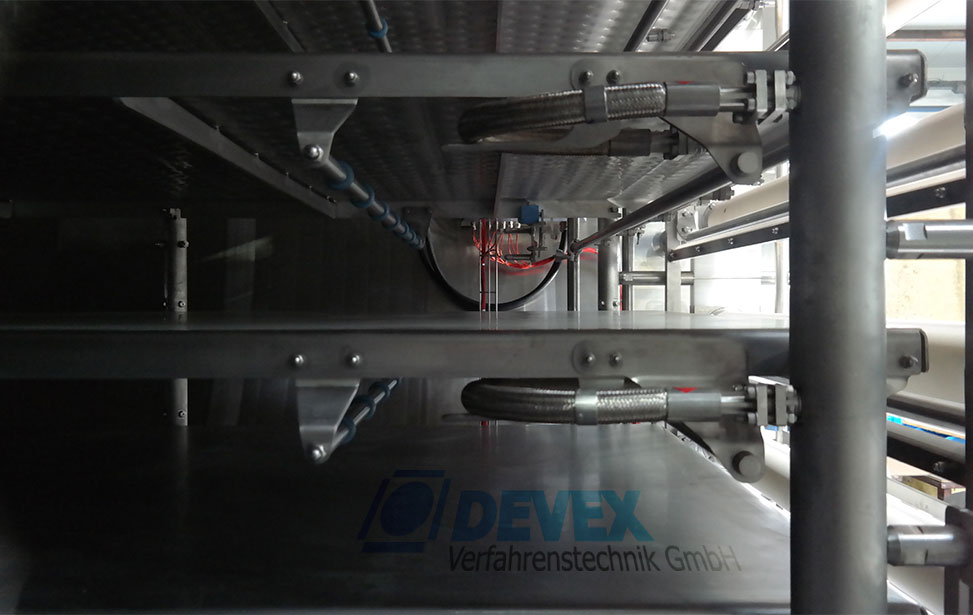

Individual temperature zones

The modular design of the heating plates allows use of product-specific temperature profiles for a tailor-made drying process.

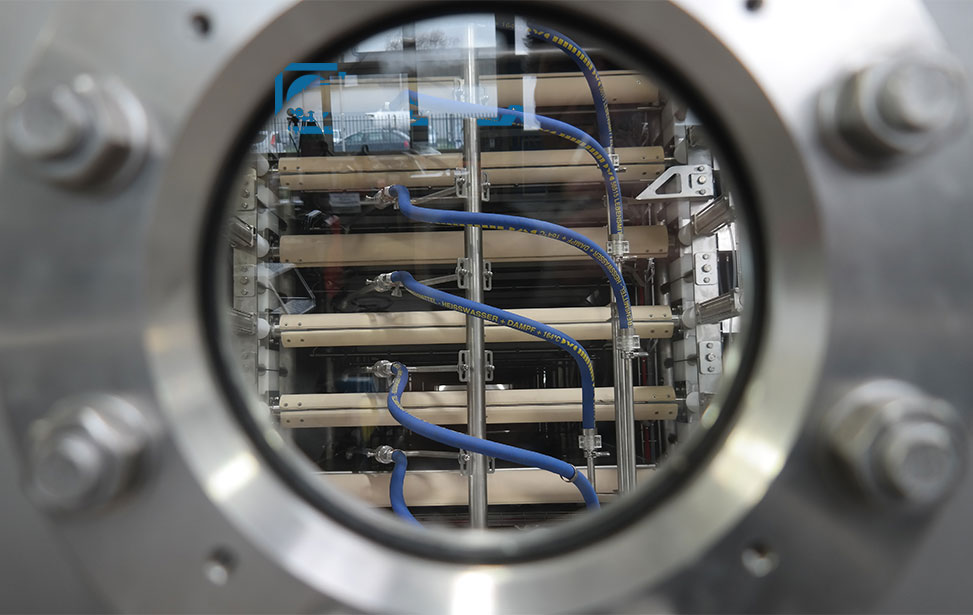

Visual Monitoring

The current drying process can be monitored continuously via sight glasses. Optionally, automated monitoring systems are available.

Maintainability

The walk-in design ensures ease of access for maintenance and servicing of the dryer equipment.