DEVEX Coffee Technology

All plants for the production of instant coffee supplied by DEVEXmeet the highest hygienic requirements. This applies to processing lines for soluble (instant) spray dried coffee powder as well as it applies to process lines for freeze dried coffee granulate.

A modern and reliable state-of-the-art technology is used for all production stages of the DEVEX plants.

Every DEVEX plant for the production of instant coffee is user-friendly and specifically designed so that it meets the requirements to the final product quantity, quality and the powder/granulate morphology. DEVEX offers instant coffee plant capacities from 50 – 1,500 kg/h.

The DEVEX Process & Product Development Department is pleased to present you the complete processing line for the production of instant coffee, from the green bean to the final granulate, ready for packaging.

The instant coffee process:

The quality of coffee extract is primarily defined by the quality and blend of the coffee bean. This again is related to the specifications of the processing steps, e.g. roasting and grinding, the extraction type as well as aroma recovery and final drying.

DEVEX offers individual process concepts, developed for a maximum operational flexibility in consideration of the final product quality and the required capacity.

During the extraction process, soluble solids and aromas are highly efficiently extracted and the coffee aromas are gently obtained to achieve the desired aroma profile. The extraction process is then followed by the clarification of the coffee extract. Afterwards, the extract is concentrated under vacuum at gentle temperatures. The generated aromas are then mixed with the extracted concentrate to adjust to required flavor. This standardized aromatic coffee extract can either be bottled or spray or freeze dried.

In the freeze drying process the coffee extract is first of all frozen and afterwards fed to a milling and sieving system in order to obtain the desired grain size. The freezing tunnel, in which the coffee extract is frozen, is a DEVEX in-house development and can be used for many more products.

Extraction unit of a DEVEX instant coffee plant

Extraction unit of a DEVEX instant coffee plant

Ice Condensation

Ice Condenser and Vacuum System of a DEVEX Instant Coffee Plant

Freeze Dryer

Tray Freeze Dryer of a DEVEX Instant Coffee Plant

Video Surveillance

Video streams from the cold room for the monitoring of the process steps

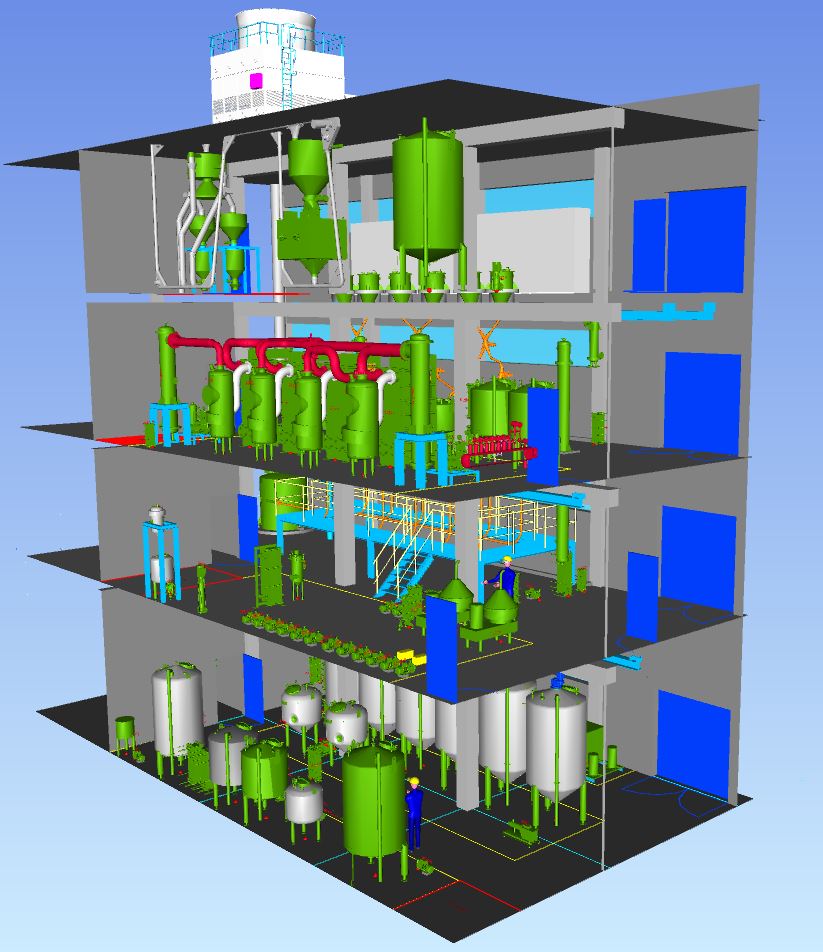

3D model of an instant coffee plant

From ground coffee to concentrate storage (front view)

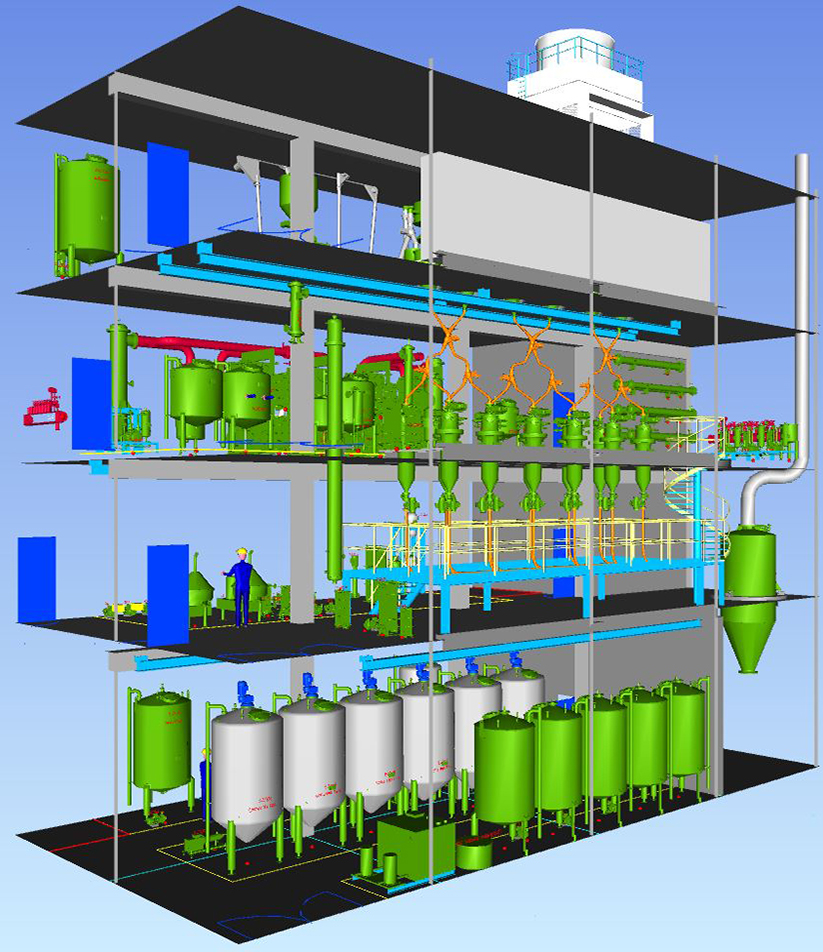

3D model of an instant coffee plant

From ground coffee to concentrate storage (rear view)

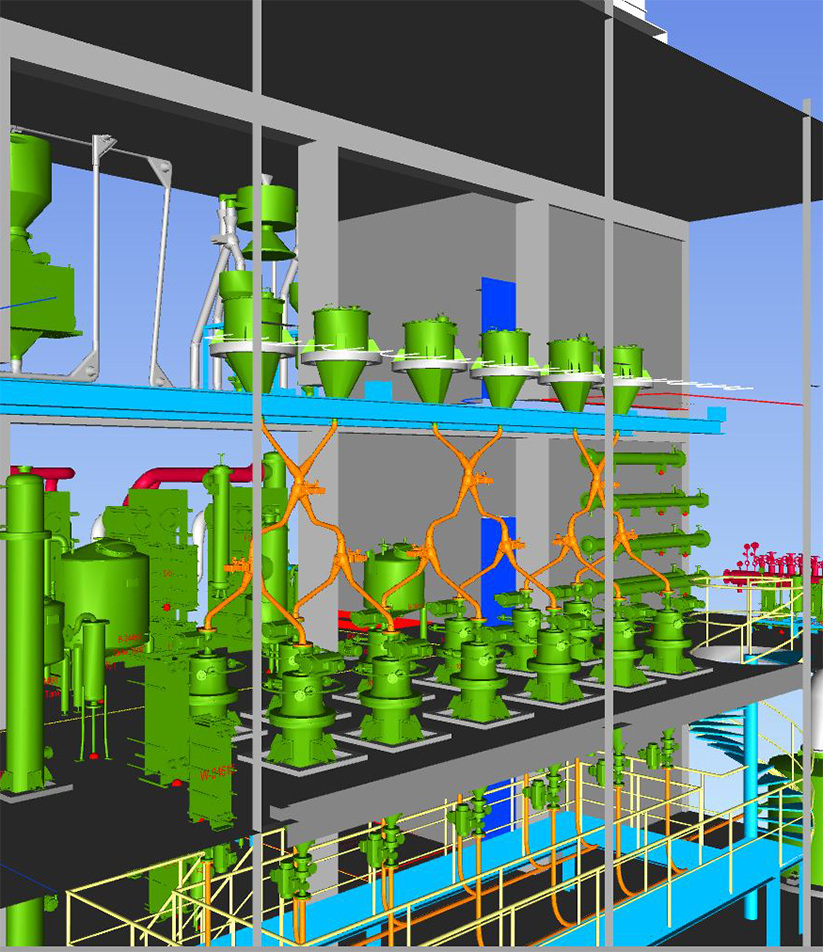

3D model detail

Ground coffee buffering and extraction battery